High-Rise

Material Handling

Made Easy

High-Rise Construction Hoists and Platforms

High-rise contractors using DOC® to move materials instead of the elevators can save hundreds of thousands of dollars on labor costs over the course of the project.

Move materials throughout a building without slowing down the elevator or tower crane.

Our complete material hoisting systems take the load off tower cranes and elevators, resulting in earlier completion and lower labor costs compared to alternative methods.

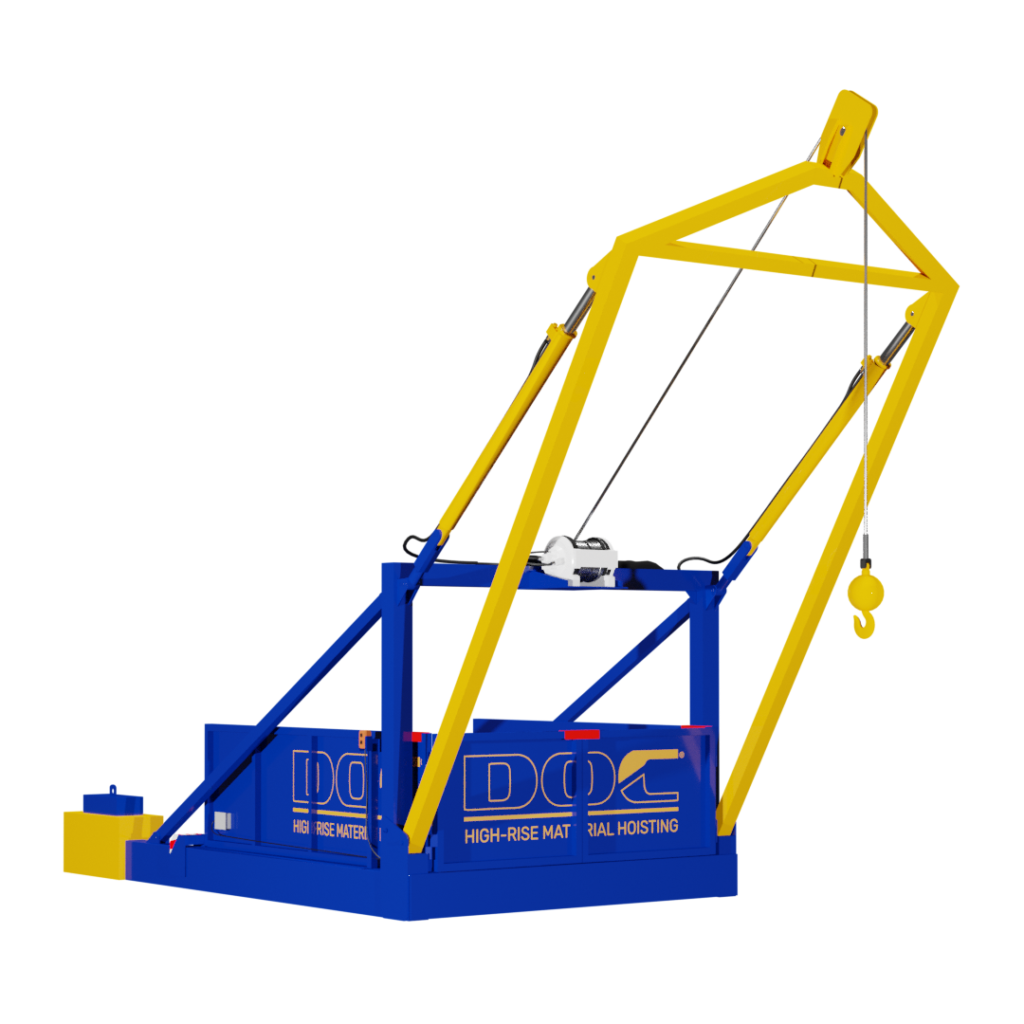

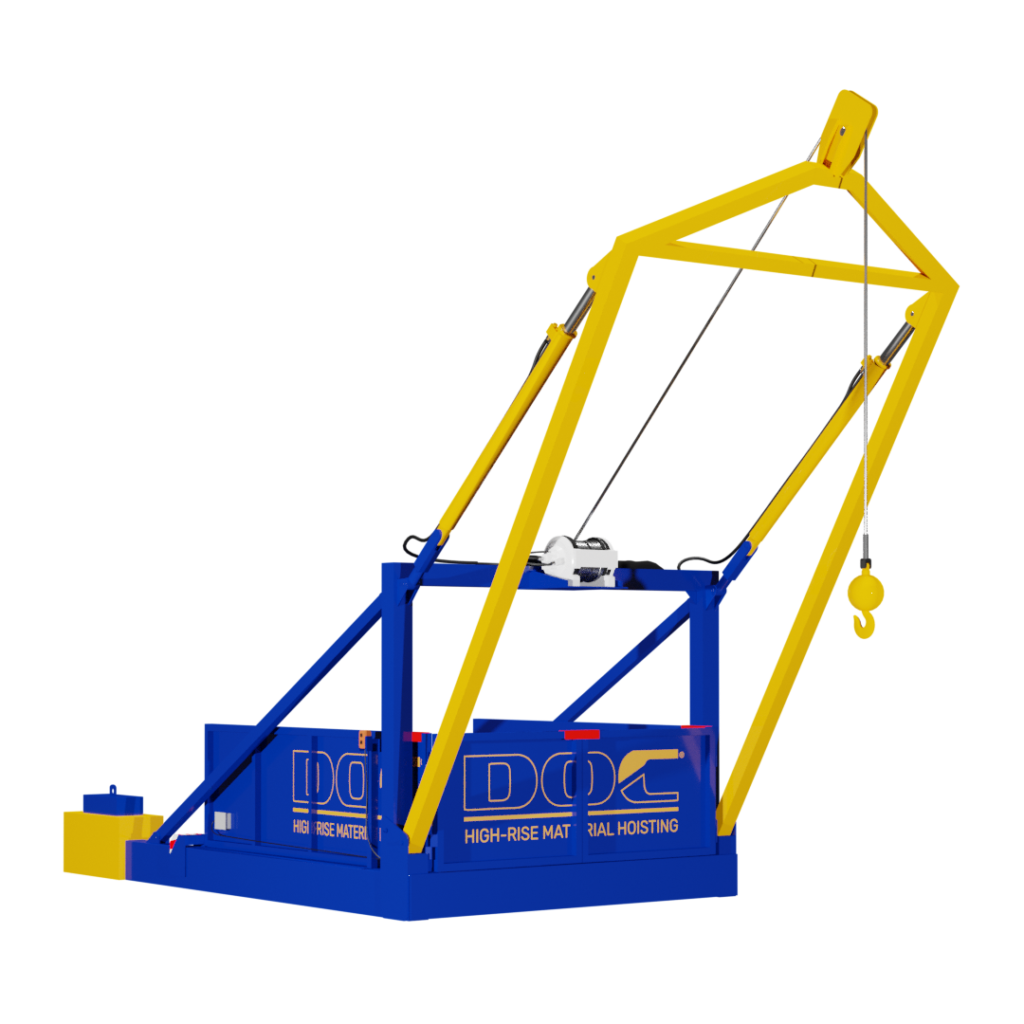

The DOC Material Hoist can be used to supply a steady stream of materials from truck to floor, without slowing down the crane or clogging the elevator.

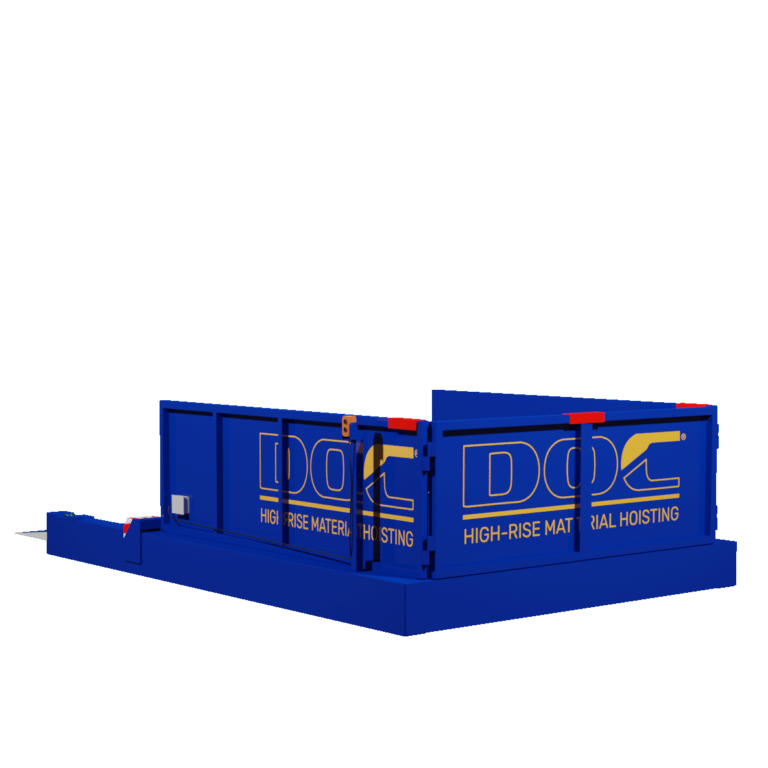

DOC® Loading Decks

and for rent

DOC® Material Hoist

The benefits of adding a DOC® Material Hoisting System are hard to ignore:

- Significantly reduce overtime labor costs

- Speed up project timelines

- Improve site safety

- Keep tower crane on-task

- Free up elevators to move more people

- Keep construction waste out of elevators

- Move large materials like pipe & curtainwall

- Unload trucks faster with less street congestion

Are contractors loading materials in elevators?

Let contractors unload their materials right off the trucks without the hassle of hand-loading materials into elevators, and save considerable labor and overtime costs.

Are you missing project deadlines and milestones?

When the tower crane is busy, many choose to move materials after-hours or on weekends to stay on schedule. Save considerable costs and speed up timelines by moving materials during normal jobsite hours.

How do I know that a DOC system is right for my project?

We’ve designed our hoisting systems to fit most types of high-rise construction projects. Steel, concrete or wood-framed, new build or renovation, our hoist can be installed in most construction and building types.

Made in the USA

We manufacture our equipment using quality steel and components right here in the USA, with a Service and Support team built to match. Give us a call to speak with a DOC representative today.

Ready to supercharge your high-rise construction project?

Just provide us with a few details to get started…

Download the DOC® Brochure

Our PDF brochure contains key features of the full line of DOC hoisting products, and includes detailed engineering specifications to go over with your team.